Do we test our ingredients for Ethylene Oxide (ETO)?

We regularly risk assess all our products during the approval process, this includes the risk of ETO.

Regulatory Context

- In the EU, the use of ETO in food additives is prohibited under Regulation (EU) 231/2012, which also sets stringent Maximum Residue Levels (MRL). For food additives, the MRL is defined as the "sum of ethylene oxide and 2-chloro-ethanol expressed in ethylene oxide" and is set at 0.1 mg/kg (amended under Regulation (EU) 2022/1396).

- MRLs for certain food products vary by category and are outlined in Regulation (EU) No 2015/868.

- The prohibition reflects the lack of safe health-based guidance values and the risks associated with ETO exposure.

Why ETO Testing Is Necessary

In September 2020, the European Rapid Alert System for Food and Feed (RASFF) reported contamination of sesame seeds originating from India. Subsequent investigations confirmed ETO contamination in other materials such as plant-based, mineral origin, and food additives from multiple countries. These events highlight the need for stringent monitoring to safeguard consumers.

Our Approach to ETO Testing

Risk-Based Testing

Cambridge Commodities employs a risk-based testing strategy to manage the potential for ETO contamination effectively:

- High-Risk Ingredients: Testing is prioritised for high-risk products, especially those of natural origin or newly approved/reapproved materials.

- Customer Requests: Non-high-risk products are tested upon specific customer request.

Testing is conducted in well-known, accredited laboratories in the UK or EU. These laboratories utilise GC-MS/MS methods, which are highly reliable and meet current regulatory standards.

Approval Process

Our robust approval process, detailed in QM07.SOP08, ensures comprehensive risk assessment at every stage:

- Country of Origin: Analysing the material's source and country of origin.

- Horizon Scanning: Monitoring industry trends and emerging risks.

- Supplier Assurance: Regularly reassessing supplier practices and goods assurance processes.

- Shipping Conditions: Evaluating transport conditions for potential contamination risks.

- Product Analysis: Conducting specific analysis for high-risk materials.

- Reassessment: Triggering re-evaluation in response to positive detections or changes in any of the above factors.

Supplier Cooperation

We work closely with our suppliers to ensure that:

- Products are EU and UK compliant.

- ETO is not used at any stage of production, processing, or transport.

We will continue monitoring the risk associated with Ethylene Oxide contamination.

Free from Ethylene Oxide Confirmation

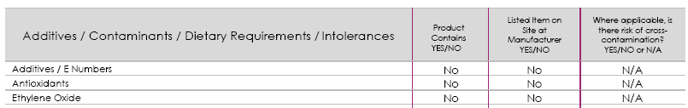

Confirmation that a product does not contain Ethylene oxide (ETO) can be found on the product technical dossier in the Additives / Contaminants / Dietary Requirements / Intolerances table.